Pre-Stage, Launch Fast

- Staging lab powers up every node before it ships

- Firmware flashed to the golden image you approve

- Asset tags & rail kits boxed together – no floor-time waste

Precision Mount – Zero DOA

- Torque-verified fasteners

- ESD straps + clean-glove protocol for board safety

- Each node boots to POST before the next one mounts

Airflow & Cable Harmony

- Velcro, not zip-ties, keeps bend-radius intact

- Colour routes separate power, management and data paths

- Hot-aisle / cold-aisle gaps measured and documented

Power & Network Verified in One Pass

- C-13/C-19 draws logged; phase balance checked on the PDU LCD

- LLDP scan confirms port location and switch stack ID

- Failures fixed before we leave—no punch-list surprises

Why Rack-and-Stack Isn’t Just “Screw-Turners”

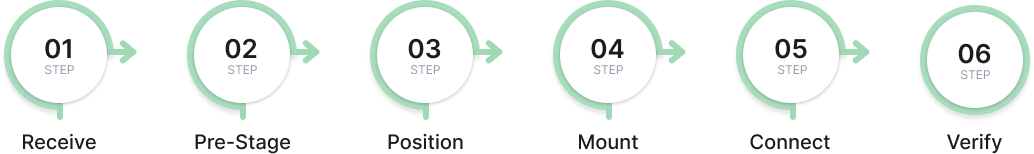

Six-Step Deployment Framework

Receive & Check

- Verify part numbers, count, and damage on arrival

- Create intake log linked to your PO or ticket ID

Pre-Stage & Burn-In

- 4-hour power-cycle, firmware patch, and SMART check

- Label rails, cables, asset tags to match rack map

Position & Rail

- Lift-cart to rack row; seismic anchors if required

- Rails fixed to OEM spec—no racking-by-eye shortcuts

Mount & Secure

- Insert hardware, insert drive trays, hand-tighten thumbscrews

- Clip cable managers but leave service loops for field swaps

Connect & Dress

- Route power left, data right; patch to pre-defined switches

- Fibre dressed in 3 m slack loops inside vertical manager

Verify & Handover

- Boot-up pass, LLDP/ARP check, PDU load logged

- Deliver “rack passport” PDF: assets, rail torque, port map

Success Stories

Frequently Asked Questions

Ready for a

Risk-Free Decom?