Know Before You Move

- Application-level mapping—no surprises mid-cutover

- Real-time dependency graph highlights hidden cross-connects

- Pre-flight checklists signed by your ops and ours

Live-Workload Extraction – Service Never Sleeps

- Maintenance-window scheduling keeps customer traffic online

- Torque-limited tools and ESD controls protect hardware health

- Rollback kits staged onsite for instant re-seat if required

Shielded Transit, Minute-by-Minute Tracking

- Climate-controlled trailers; vibration dampers to <0.5 G

- Live GPS feed with geofence alerts direct to your inbox

- Customs, carnets, and export licences handled in advance

Power-Up & Validation at Destination

- BIOS scrub, firmware parity, and serial confirmation

- Dual-stack network tests: ping, throughput, latency baseline

- Snap-back plan until your team issues “all-green” sign-off

Migration vs. Simple Moving – Why Engineering Wins

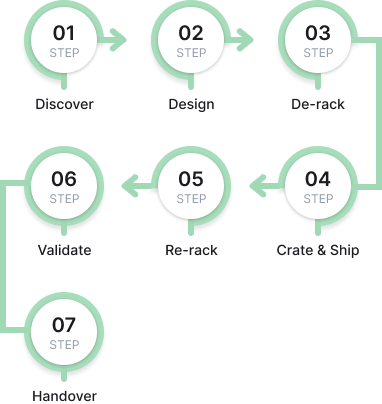

Our Seven-Step Migration Framework

Discovery & Design

- Dependency scan, performance baselines, rollback criteria

- Joint change-control workshop; MOP/SOP agreed and logged

Hardware Prep & Label

- Asset-tag + color-code cabling for rapid reconnect

- Capture pre-move photos for plug-by-plug reference

Controlled De-rack

- Power drain, cable pull, anti-static bagging

- Source-site remains online except for gear being lifted

Crate, Ship, Track

- Shock sensors, humidity loggers, live GPS ping every 15 min

- Customs and bonded-escort options for cross-border legs

Re-rack & Cable

- Laser-level rails, pre-terminated fibres, torque-verified lugs

- Follow original photo map—zero guesswork reconnect

Validation & Cut-over

- Boot-time compare, checksum verification, application smoke test

- Business signs off before traffic swings to new rack

Project Close & Handover

- Deliver post-move runbook, updated CMDB export, warranty notes

- Optional Smart-Hands retainer for 30-day hyper-care

Success Stories

Frequently Asked Questions

Ready for a

Risk-Free Decom?